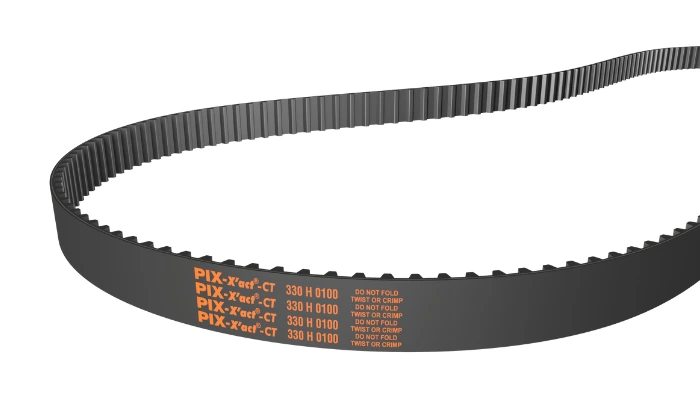

PIX-X'act®-CT Classical Timing Belts

Product Range

| Section | Pitch (p) (mm) |

Tooth Height (h) (mm) |

Belt Thickness (Th) (mm) |

Manufacturing Range | Length Designation | Sleeve Width | Additional Product Details |

|

|---|---|---|---|---|---|---|---|---|

| Min. (inch) |

Max. (inch) |

|||||||

| MXL | 2.032 | 0.51 | 1.14 | 2.1 | 177.1 | Lp | 450 | |

| XXL | 3.175 | 0.76 | 1.52 | 5.0 | 21.90 | Lp | 450 | |

| XL | 5.080 | 1.27 | 2.30 | 4.4 | 212.8 | Lp | 465 | |

| L | 9.525 | 1.91 | 3.60 | 6.7 | 270.0 | Lp | 465 | |

| H |

12.700 | 2.29 | 4.30 | 14.5 | 272.0 | Lp | 465 | |

| XH | 22.225 | 6.35 | 11.20 | 46.3 | 227.5 | Lp | 430 | |

| XXH | 31.750 | 9.53 | 15.70 | 62.5 | 200.0 | Lp | 430 | |

Timing Belts are one of the most important part of Power Transmission drives. Timing Belt can be best described as Belt with integrally moulded teeth on its inside which makes positive engagement with axially grooved pulley. Timing Belt is also known as synchronous Belt or positive-drive Belt. Timing Belt drive is not considered as a substitute or replacement to other modes of Belt drives.

Timing Belts exhibit important properties such as fixed speed ratio, no re-tensioning after installation, low maintenance with wide variety of power transmission capacities and drive speeds.

Timing belts use teeth that mesh with grooves in a pulley to synchronously drive the system. There is no slippage, which will cause speed variations, allowing drives to be timed very accurately. The tensile cord has minimal stretch so the constant need for take up adjustment is removed.

Timing drives will work over a very wide range of speed and torques. Torque ranges of between very light office equipment to heavy duty crushing equipment up to several hundred kW are also capable of being driven by timing drives.

Its unique feature enables it to use in positive drive resulting in precise movement of drive components.

Timing Belts are offered in three different teeth profile:

- Classical Timing Belts,

- High Torque Drive (HTD) Belts and

- Super Torque Drive (STD) Belts