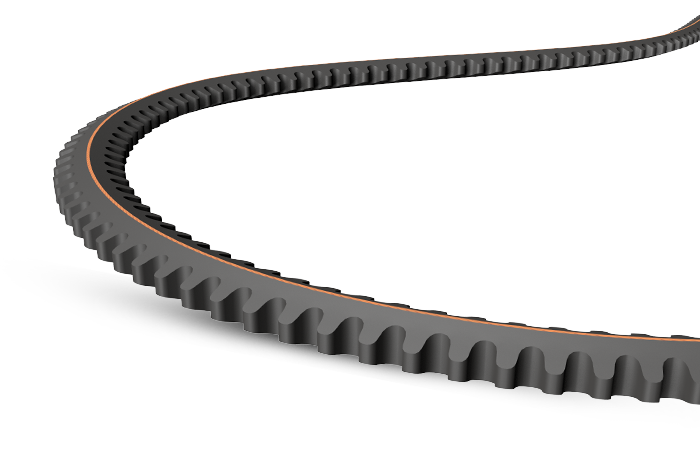

PIX-DUO®-XS Twin-power, Hexagonal Wrap Belts

Product Range

| Section | Top Width (Tw) (mm) |

Thickness (Th) (mm) |

Angle (θ) (Degree) |

Manufacturing Range | Length Designation | Additional Product Details |

|

|---|---|---|---|---|---|---|---|

| Min. (inch/mm) |

Max. (inch/mm) |

||||||

| AA | 13.0 | 10.0 | 40 | 48 | 258 | Le | |

| BB | 17.0 | 14.0 | 40 | 43 | 930 | Le | |

| CC | 22.0 | 17.0 | 40 | 77 | 930 | Le | |

| 25 | 25.0 | 22.0 | 40 | 92 | 925 | Le | |

Hexagonal or Double V Belts are recommended for serpentine drives, where power is to be transmitted from both the sides of the Belt.

Double V Belts are designed with special tension cord for meeting dual power requirement along with multiple bends. Double V Belts provide amazing torque, strength, durability and are used on drives with more or more reverse bends.

They are meant for the application where sudden directional changes in the Belt travel occurs, these changes exert unique stress on the structure of the Belt. PIX-Double V Belts are perfectly designed and remain aligned both laterally and longitudinally, in the pulley groove, while operating. PIX Hexagonal or Double V Belts are antistatic and oil resistant.

Double V Belts are widely used in agricultural machinery, rice mills, husker machines, dyeing units, poultry feather pickers, etc.